Although it is not directly related to the purpose(s) of this notebook, without the freedom to investigate, test, evaluate and share information about shooting, firearms, ammunition, ammunition construction and so forth this notebook is useless.

In the coming months it may

become necessary to organize, support and defend each other from

those who would disarm us.

One good, simple idea to start with is Free

Territory Alliance I recommend you carefully read and if

you agree take the oath. You won't be alone!

Late December, I finally after a lot of difficulty, got the web server configured to respond to SSL (https://) requests on both domains (SnellsNotebook.us and Snell.ddns.net) - no doubt there will be more to do, but for the next 90 days or so, it should work, then we have to figure out automatic renewal. In case you are interested, I am using certificates issued by 'Lets Encrypt' an effort to enable no-cost (free!) encryption across the entire internet.

The Accurate MSR Saga Continues

20200701 Update (under development)

20201200 Additional load development on hold due to component

shortages.

20201200 Maybe my next barrel for the Accurate MSR should be a

long 1:12 twist that can shoot Hornady SPSX varmint

bullets? Seems like those bullets are rarely in short

supply (except lately) and they have always shot very well in my

22-250's ... I know they won't be good for exceptional long

range, but they might work out for ground squirrels to 500 or

more.

20200701 Update (under development)

What's the point of all of these barrel surveys?

In order to understand what we are looking at when we 'bore-scope' a barrel, I'm building a library of in-bore images starting with barrels I own.

The library will eventually be presented as a searchable database that will contain an image or video, what the observation was, what the situation was; how did it get this way, and what conditions were present when the image was taken. From this database, I hope to be able to provide a means for you to resolve what you observe in your barrel.

Until the database is ready, I will be posting all of the data I have collected as directories (folders for you Microsoft types) full of image files. I will try to put a 'ReadMe' file in the directory to tell you what the images represent, what conditions were present, and how the images were taken. So far there are brand new high performance barrels (see the Volquartsen Victory Barrel) with exceptionally well finished interior, and a Proof Research button rifled barrel (they don't do button rifling any longer), a Ruger barrel formed on a mandrel by a hammer forge, and some others. Only the S&W Victory factory barrel has a definitive problem, and maybe the Stag 15 Varmint barrel - the jury is still out on that one, but it may have a chamber that is not co-linear to the bore. The 6.5 Creedmoor (Ruger) barrel does not have many rounds through it, but already shows some "alarming" indications of fire cracking and throat erosion. There are images of that barrel after being stored over a year without cleaning and after a deep cleaning.

So you might be able to use what I've done so far compare to your own in-bore images to get a quality assessment by comparison.

NOTE: These images and videos are served locally.

Barrel Survey Listing by Firearm

BARREL SURVEYS

Smith & Wesson Victory - Factory Barrel with chamber and rifling defects.

NOTE: I purchased the

pistol with this barrel installed, discovered the terrible

machining and QA, purchased a Volquartsen carbon barrel,

contacted S&W Customer Service, asked if I could just return

the barrel and received the response that they had to have the

entire pistol.

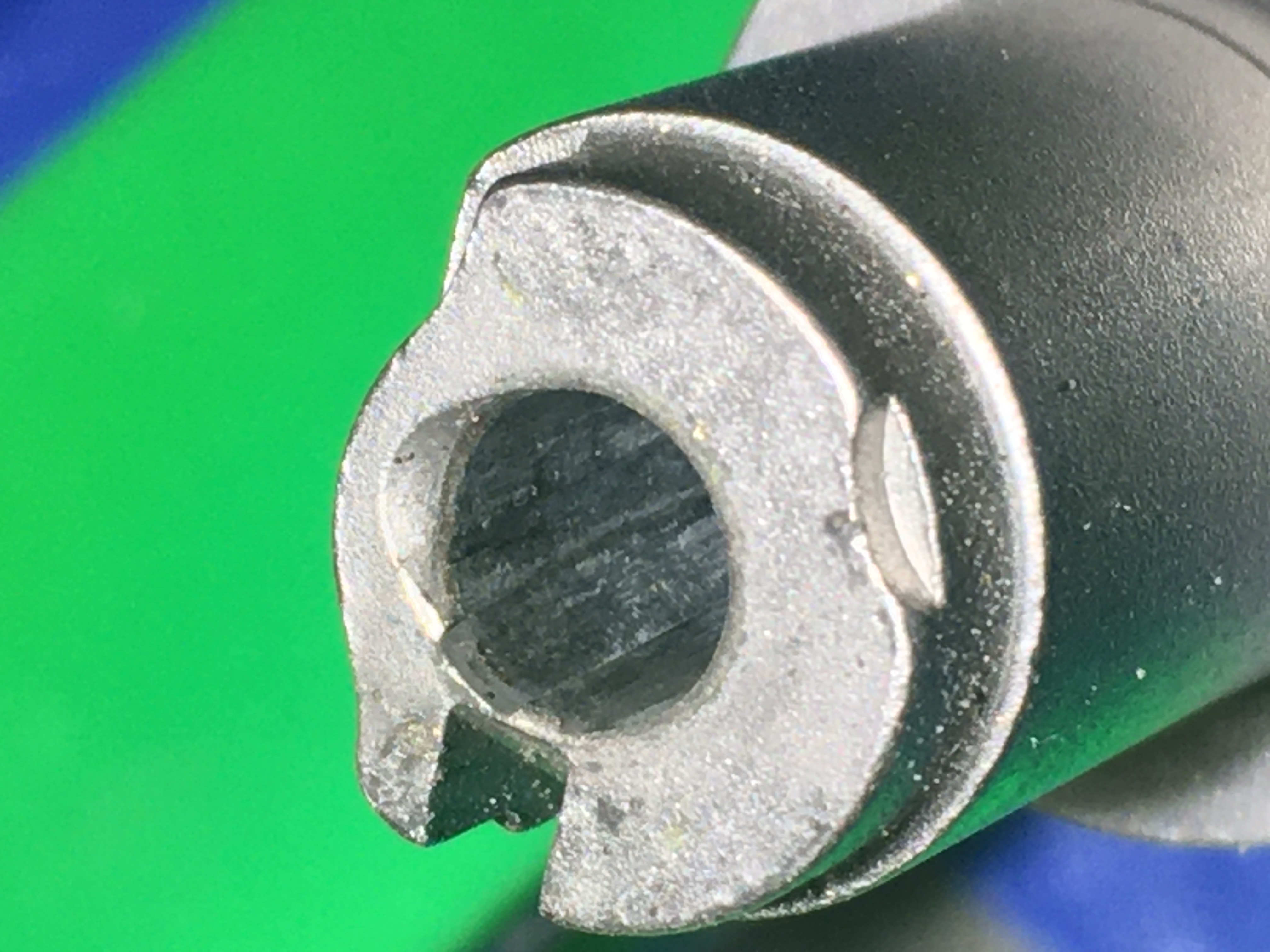

The Factory barrel's chamber has a rifling groove that appears

at 3 O'Clock right next to the extractor cut, this groove cuts

right through what should be the right side of the

chamber. Following this groove with the camera reveals

that there are some places along its length where the rifling

tool appears to have chattered significantly leaving divots

which instantly leaded up. As a matter of fact, the

chamber, and first 1/3 of the barrel were so severely leaded

after 300 rounds that it took two days of intermittent work with

brushes, patches, J-B Bore Cleaner (abrasive), KG 2, Hoppies #9,

nylon and bronze brushes, and about a hundred patches to get the

leading down to barely noticeable (it's still not gone, and I'm

willing to bet if the barrel is shot again it will lead up

instantly again).

S&W Victory Barrel Survey 20201116 - after trying to remove excessive leading.

After extensive cleaning using several abrasive cleaners including J-M Bore cleaner.

There is a nick in a rifling groove which has caused a lot of leading at this location.

There are several of these present.

20201008 S&W Victory Factory Barrel Survey Videos and Stills

20201014 S&W Victory Factory Barrel Survey Videos and Stills

20201116 S&W Victory Factory Barrel Survey Videos and Stills

20201119 Volquartsen Carbon Barrel Survey (this is what a barrel should look like!)

D.Rhodes Weatherby MKV 270 Wby (belted) Magnum

Before carbon removal.

20230802 - 90 degree view before carbon removal 6:18.

20230802 - 0 degree view before carbon removal 1:53.

20230802 - Lug snapshot

After carbon removal.

20230803 - Transverse marks on Lands snapshot.

20230803 - Traverse marks on lands and grooves snapshot.

20230805 - Traverse marks on lands and grooves2 snapshot.

20230805 - Scope base screw penetration in lug recess snapshot.

20230803 - Chamber belt recess 0:25.

20230803 - Chamber, Leade, Forcing Cone, PMax & Copper near muzzle and crown 4:26

20230805 - Rear base screw holes 0:22.

Discussion of Wx, Temp, Pressure and Altitude as it relates to Density Altitude and to Ballistics.

Relative Importance of Sources of Dispersion; Pointing Error, Velocity Variation, Wind, Distance, Marksmanship, etc. etc.

Scope Mounting For Long Range Shooting:

Rifle Level, Scope Canted

Rifle Canted, Scope Level

Rifle and Scope Canted with a correctly installed scope

Notebook Notes

Notes

on Ballistics Apps

Exterior Ballistics - Wind Effects

Future Plans

Training

Scripts