BACK TO: HOME

FORWARD TO: INITIAL PHYSICS

Contact me: John@SnellsNotebook.us - Last Updated: 23 NOVEMBER 2020

BACK TO HOME

I started out to simply try to find the most accurate load for my rifle. At the time, all of the published information said to just keep trying different powder charges, bullets and primers. Although I looked in many reloading manuals, and read ever periodical I could find, I was unable to learn of any methodical way to adjust loads to produce accuracy. I did however find a tremendous amount of non-sense, circular logic, and flowery words without meaning. As the result, I started to research the topic on the Internet. Eventually, between some very old periodical articles, and some very new Internet postings, I was able to assemble a fact based logical approach to economic load development of accurate (small group) ammunition.

As the information began to accumulate, I found myself interested in publishing my findings so that the next hand loader could find and benefit from my research.

Of course, many other topics came up, and questions were asked. So I decided to compile what I know and what I believe to be true into an indexed web page.

What follows is the result.

I have found that a short concise list of safety rules is much

easier to teach, learn, and use.

The immortal Col. Jeff Cooper

posited four simple rules that I believe are sufficient for all

cases.

Rule 1: All guns are loaded at all times.

Rule 2: Never point a gun at anything you don't want to destroy.

Rule 3: Keep your finger off the trigger until you are ready to shoot.

Rule 4: Be certain of your target and beyond.

If you always do these four things you will never be the cause of

a shooting accident.

Lets look a little closer at the rules to

see how they are applied in daily use.

Obviously that can not be true all of the time, but if you TREAT

all guns as if they are loaded at all times you will never point a

firearm you 'thought was unloaded' at something you didn't want to

destroy.

You should never hand another person a gun that you

have not personally inspected (cleared), and you should under most

conditions open the action, and confirm that the gun is unloaded

before you pass control of it to another.

To clear a gun you

open the chamber, (where the bullets go to be fired), and inspect

the

gun to ensure there is no ammunition in the chamber. Further, with

regard to repeating arms you should also inspect the magazine,

(where

the bullets are carried before they are loaded into the chamber),

to

ensure there are is no ammunition waiting to be loaded.

A

cleared gun is one that has been inspected to ensure there is no

ammunition loaded or waiting to be loaded.

The exceptions to

rule one, that I can think of at the moment are:

If you are teaching someone to shoot, you may load the gun for them, put the gun on safe and hand it to them. This should be done so that the student has a full and complete view and explanation of how the gun is loaded, and what additional steps are necessary to make the gun ready to fire. This activity should be conducted on the range, and the instructor is responsible for ensuring safe range operation.

If you are in a situation where you must use a gun for self defense, or where you must provide a gun to someone for self defense immediately, it would not be unreasonable to pass a loaded firearm from one to another. The firearm safety should be engaged prior to passing the weapon. This is an inherently risky operation, and should be anticipated in training.

These are NOT exceptions:

Crossing a fence. If you hand your gun to another person during a maneuver, for example; crossing a fence, the gun should be unloaded, cleared and then handed to the other party. The gun(s) should stay unloaded until everyone has passed the obstacle. In point of fact, hunting guns should stay unloaded until the hunt has progressed to the point where the action of loading might cause game to learn of your presence.

Casually handing a firearm to another. This is a major source of accidents! Always unload before transferring. Always check for yourself when receiving.

It seems pretty simple. With practice it can be, but without

constant vigilance it is very easy to 'cover' ie 'point at' other

people in your vicinity. For example if you are hunting, and

carrying

your rifle in two hands, you must be aware when turning that your

muzzle does not 'sweep', 'cover' or 'point at' any person or thing

that you don't want to destroy.

Pointing your muzzle up, down,

or to the side is acceptable. If your gun should accidentally

discharge with the muzzle pointed straight up, your bullet may not

have killing power when it returns to earth.

Mythbusters did

a very thorough analysis of the subject and found that a bullet

fired

straight up lost gyroscopic stability near the top of its flight,

and

then fell to earth sideways. While the returning bullet might hurt

if

it hit your head, it would not contain sufficient velocity and

stability to penetrate deeply. However, if a gun is fired on any

angle other than straight up there is a likelihood that the bullet

will retain gyroscopic stability and velocity sufficient to case

damage or death upon return to earth. The danger range for such is

on

the order of 3 miles.

If you point your muzzle down and the

gun discharges, your bullet may be absorbed by the earth at your

feet. (assuming you didn't shoot yourself in the foot), or it may

encounter rocks which may cause the bullet to break up and

'splash'

in all directions (your legs are closest!). If your gun is pointed

some distance away and down, the bullet could ricochet (bounce)

and

travel miles before loosing lethal energy.

The military has

found that on those occasions when carry a loaded weapon inside a

vehicle is appropriate, that pointing the muzzle down is generally

the best solution. In helicopters and automobiles bullets fired

down

will do the least damage.

For non-combat applications,

keeping your weapon unloaded until just before firing is the best

way

to ensure that whatever you may point at is not likely to be

destroyed.

For combat applications (daily CCW carry, armed

response to attackers etc.) you must train often to ensure that

your

muzzle discipline is as near perfect as possible. This involves

training with everyone who may be involved with the operation e.g.

family members etc.

If you draw a pistol from its holster or

place of concealment you might point it at yourself or others. A

right handed shooter drawing from a right side holster using a

conventional muzzle down, butt to the rear carry at the hip, will

only point his or her muzzle down, then rotate vertically to the

target. A shooter using a cross-draw (gun is on the side opposite

the

firing hand) likely will point the muzzle in an arc that may sweep

across any person to the shooter's weak (non-firing) side and/or

front. A shooter using a back of the spine holster may point at

themselves around the hips and legs, and must make an effort in

training to control where the muzzle points, as it is all too easy

to

raise the muzzle early and sweep yourself on the strong side, or

anyone to your stong side. A person using an appendix carry (in

front

of the hip) is very likely to point the muzzle at their own body

during a draw, and must be careful to not sweep to the weak side.

A

person utilizing off-body carry, for example a purse, typically

has

the same problem as a shooter using a shoulder holster or a cross

draw holster. These are the reasons for Rule 3.

To ensure you

are safe drawing your weapon, practice in front of a mirror while

drawing slowly and deliberately. Observe the path of the muzzle.

As

you gain skill, increase your draw speed, and continue to observe

the

muzzle until you are confidant that no outside force applied

during

your draw can cause unintended mayhem.

As you may have imagined if you followed the discussion about rule 2, there are times when your gun may be pointed somewhere you didn't really want to point it. As long as the guns safety is on, and the trigger can not be pulled inadvertently, there is still a safety margin during these events. Some modern firearms have only one safety mechanism - a small blade within the trigger that only unlocks when a finger (or something like a finger) is pressing on the trigger. Other firearms have additional safety mechanisms. To my knowledge the venerable 1911 semi-automatic pistol has the most at six separate safety mechanisms.

Modern striker fired pistols based on principles similar to the GLOCK series have these features:

1. Trigger Blade. If the trigger blade is not depressed, the trigger can not fire the gun.

2. Trigger disconnector (same as 1911 above).

On some modern pistols there is a 'magazine disconnector' which is designed to prevent the gun from firing if the magazine is removed. The theory is that as a last resort you could eject the magazine before the weapon leaves your control. Perhaps moderately useful during storage to prevent children from activating unsecured guns, while permitting quick action by only inserting a magazine. In most cases a magazine disconnector is a death trap waiting to be sprung on the shooter who has one round in the chamber and is the midst of reloading. That round CAN NOT BE FIRED until the magazine is fully inserted, and MIGHT be fired inadvertently if the trigger is being pulled while the magazine is inserted. Firearms having magazine disconnectors require additional extensive training to avoid all the problems they create.

3. Loaded chamber indicator. This is usually the extractor which is designed so that when a case is present in the chamber it rests proud of the surface. It is always tactile, and sometimes visual.

4. Manual safety. On some striker fired pistols the manufacturer has included a manual safety that typically operates similar to the 1911. When not present, and a DA/SA trigger is in use, the decocker may be present. It's purpose is to relax the main spring by lowering the hammer against a stop that prevents the hammer from reaching the firing pin.

5. Trigger Guard.

Some semi-automatic pistols rely on a heavy and/or long trigger pull to prevent accidental discharge. These are sometimes referred to as DA/SA (Double Action / Single Action) triggers.

DA pistols (as opposed to revolvers) featuring a long heavy first shot trigger pull, followed by much lighter subsequent trigger pulls are not my favorites. The second shot followup is always going off before the sight picture is correct (because the trigger is so much lighter than it was a split second ago), and typically these pistols require a 'decocking' mechanism, to return to a safe (and long heavy trigger pull). I find the decocker to be one of the most 'evil' inventions, right up there with magazine disconnectors! It is just plain wrong to allow a hammer to fall when not either firing, or dry firing. I can not make myself 'believe' in the safety of the mechanism, and I don't like the abrupt stop the hammer experiences because this is the road to fatigued metal. In any case, if you own one of the pistols with this feature (Walther PPK, S&W, etc.) please train yourself and remember all the rules of firearms safety apply at all times, so NEVER EVER operate a decocker with the muzzle pointed in an unsafe direction. Always get your finger off the trigger and out of the trigger guard before decocking any of these style pistols.

Modern revolver safeties generally consist of the following: Bars that must be moved into position between the hammer and the firing pin by action of the trigger to allow transfer of the hammer energy to the firing pin. Firing pins that do not have the mass to detonate a primer no matter how hard the revolver may fall, and various mechanisms to ensure the alignment of the chamber with the barrel at the moment of firing. They are strong guns with substantial frames made from high strength materials and can withstand much higher operating pressure than older revolvers.

Antique revolvers safeties generally consist of making sure you don't carry a live round in the chamber that is under the hammer. This is accomplished by loading one round, skipping one round, and loading 4 more rounds in sequence, then cocking and lowering the hammer on the empty chamber. Its a skill you should develop early in your training on an antique revolver like the Colt SSA. Failure to abide by the rule to keep an empty chamber will (not may) cause the gun to fire when the hammer is struck. Immediately unload or reload the revolver and make sure the hammer rests on an empty chamber after firing. Simply easing the hammer down, or using the half cock notch will result in undesirable conditions.

Revolvers come in two types, single action, where the hammer is cocked manually for each shot, and double action, where the trigger can be used to cock and fire the revolver in one continuous motion. Modern double action revolvers invariably possess single action capability in addition.

As you can see, a lot of thought has gone into making guns safe. A safe gun is one that will not discharge inadvertently, but will fire instantly when the operator so chooses. The trigger is the final safety. To defeat the final safety only requires some amount of pull and the gun will fire if it can. If you put your finger into the trigger guard, you have provided a means for external forces (think the side of your holster, or an opponent) to mimic pulling the trigger. Keeping your finger (and everything else) out of the trigger guard area eliminates the threat that the gun can fire due to negligent handling. In particular keep your finger off the trigger AFTER you have ceased firing and MOST ESPECIALLY, keep your finger off the trigger when re-holstering your gun. Train yourself by performing slow draw, aim, fire and re-holster drills. With an unloaded gun, watch what happens if your trigger finger stays in the trigger guard. Some holster designs will cause you to press the trigger. Know your equipment. Always train the way you want to fight.

Do not shoot at things you can not positively identify. A very large percentage of accidental shootings happen because the shooter does not take time to positively identify the target before firing. Know you are shooting at the correct target, and conversely know that if you bullet penetrates your target it will not damage anything around or beyond the target. For example if you are hunting and a shot at a great trophy appears on the crest of a hill, you should wait until the animal moves off the crest of the hill, so that a hit or a miss will land where you know the background. Shooting over hills, and across bodies of water, and along or across roads have been responsible for many firearms accidents. There is one time, and only one time when you shouldn't spend too much time worrying about the background, or where your bullet may go, and that is when you are forced to fire on another human. In that one case, most courts have held that any damage resulting from a justified shooting is the fault of the perpetrator rather than the victim. This is the result of the notion that all the results of a bad deed are the fault of the one committing the bad deed. You should of course be aware of your immediate surroundings, and if possible move to ensure you do not shoot into say an adjacent bedroom where you know someone to be sleeping, but in the event your are forced to fire, then fire for effect. The good news is that in your home you can plan ahead to know where safe shooting lanes are located, and you can plan ahead to use equipment and ammunition that is suited for your circumstances.

Marksmanship is the art and science of firing a hand held or shoulder fired gun.

Competition marksmen live in a world of rules. Their shooting position(s) are dictated by the rules for the discipline or the match. NRA Smallbore and High Power marksmen have prone, sitting, kneeling and standing positions to master at the same time they skill with their hardware. Tactical marksmen must master shooting from sometimes difficult positions while being able to utilize a wide range of support options. Hunters pretty much have no rules about positions, but will find that prone, sitting and standing as well as using whatever support is available are the options.

Beginners would do well to master the conventional match positions of prone, sitting, and standing first. Then master shooting from a shooting bench, and perhaps last make an effort to use kneeling until you are comfortable and accurate in that position.

Natural Point of Aim - When you have completed getting into position to shoot, close your eyes, relax all of your muscles. Count to 5. Open your eyes and check to see where the rifle is pointed. If it is not pointed directly at the place where you want the bullet to strike, adjust your position and repeat. Whey you have found your natural point of aim, you should be able to remain in that position for an extended period of time and you should not have to 'muscle' the gun to get onto or stay on the target.

Prone is considered to be the most stable position. I have found that shooting from a bench is much more stable, repeatable, comfortable, and produces much higher accuracy for most people. Bench technique is a lot more than just sit down and bang away. Lets cover some of the basics for each position:

Prone will get you out of the line of incoming fire as much as possible, allow you to sneak up on targets, and crawl around below the top of the brush etc.

Prone With Sling - In this position the shooter lays flat on their stomach, pelvis and ankles. Elbows and shoulder support the rifle. A sling connected to the front of the rifle's stock and wrapped around the 'support side' (opposite of the trigger finger) forearm and upper arm, may or may not be connected to the butt of the rifle. Properly adjusted the sling will allow the support side hand's grip to control elevation with little effort as it slides back and forth along the forend. Shooters body should align just slightly to the support side as viewed from above. The sling should be tight, and the butt of the rifle should be tight against the shoulder. Follow through the shot by riding the recoil with the rifle.

Prone with Support - In this position the shooter will be more directly in line with the rifle, and the support side arm will not be involved in supporting the rifle, as it is supported by something (bipod, backpack, etc.). The support hand can either help control the vertical by supporting the butt, or help stabilize the rifle by ensuring it doesn't fall off the support. The support hand should be available to make sight corrections (dial up the scope), or adjust parallax (on a modern long range scope). The support side hand should not in any way support the gun forward of the butt. Follow through the shot by ensuring the rifle recoils straight back into your shoulder. You may support the butt of the rifle with a bag or a mono-pod.

Sitting will get your line of sight above the grass (most of the time), allows you a little bit of lateral (tracking) movement, may offer a position you can remain in for long periods comfortably.

Sitting With Sling - Cross your legs at the ankles, or place your feet slightly apart. This position changes quite a lot based on foot position choice. In competition crossing ankles, and leaning far forward so your elbows are outside your knees is typical, and makes this position even more stable for me than prone. The open sitting position is much more suitable for hunting or tactical applications where movement is necessary. In the 'closed' position the rifle sling is employed the same way as in prone, and the rifle is held tightly to the shoulder. Follow through by ridding the rifle's recoil. In the 'open' version of this position, the elbows are placed to force the knees apart. If you have a spare rope or belt, to constrain the movement of your knees this can be a long term comfortable position. In the open version of sitting follow through is again a tight sling and riding the rifle's recoil.

Sitting With Support - This position can become difficult if you loose flexibility in your core (eg get fat), because in order for it to work well, you need to lean into the rifle and you don't have the luxury of the rifle's weight, or a sling to help with that movement. Essentially you will be in a 'kip' position, and muscle strain (bad for shooting accurately) will start immediately. Generally sitting with sling is more stable, unless terrain offers support for the shooter. There is also a 'high sitting with support' (long bipod, tripod, shooting sticks etc.) position that may include a short chair, or kneeling with both knees on the ground, while your weight rests on your heels. Follow though in these supported positions may be best if you utilize 'free recoil' - in other words, your body does not resist the recoil, and does not support the rifle. When the rifle recoils, it does so free of obstruction (for a few inches). It does not take much distance between the butt pad and the shoulder to create a free-recoil setup, however in that distance the rifle is free to accelerate and with heavy recoiling calibers that may be enough to cause problems. In free recoil you firing hand should be setup in such a way that it does not influence recoil. Many shooters put their thumb on the back of the trigger guard, and their trigger finger on the trigger, and have no other contact with the rifle. You should work up to free-recoil, its a good way to get a scope cut, drop your rifle, dislocate your shoulder, etc. Be sure you know what's going to happen. Heavy (12-13 lb) low recoil rifles (308 Winchester and below) generally have a low enough recoil impulse that free-recoil is practical and you can learn it with little risk. Don't start off with a 6 lb 7mm Magnum!

Kneeling raises your line of sight above what you had in most sitting positions. It also allows for rapidly assuming the position, and rapidly resuming stalking, or tactical movement with a minimum of noise and visual signature. The accuracy potential from kneeling is probably twice to three times better than from standing unsupported (offhand).

Kneeling With Sling - Once again a tight sling can increase your stability significantly in this position. Your support side foot should be flat on the ground, your shin straight up, your knee bent. The support side elbow should be just over the knee. The trigger finger side elbow can be down, but if you shoot a heavy recoiling rifle, putting that elbow parallel to the ground will open your shoulder pocket and allow absorbing much more recoil. Follow through in kneeling with a sling, as before, to have tight sling, and ride the rile throughout the recoil pulse.

Kneeling With Support - Generally this position only happens if you have to work from under some obstruction. Typically any shot you would take from this position can just as easily be taken from standing with support, and with about the same accuracy.

Standing, also known as 'offhand' is the most challenging position to shoot accurately from. In this position a sling is generally a detriment to accuracy. Since most hunting and tactical rifles will have a sling attached part of your training for this position will be to secure the sling so that it does not impart movement.

Standing Unsupported - In this position you will not be able to hold your sight picture for any more than a few seconds. There are at least two ways to address this problem with technique. First what I call the 'shotgun approach' which works well for quick shots on larger targets. Mount the rifle so that the sights are in the correct position instantly. Your eyes should be looking at and focused on the target as you mount the rifle. The moment the rifle is mounted, you should be able to pickup the sights. If you try to stand still you will wobble around in circles (we'll talk about that next). To keep from wobbling around you will need to muscle your gun in such a way that the sight track across the aiming point (AP). If you move too quickly this won't work as well as if you move slowly and deliberately. The amount of movement is very small, maybe not more than 2-3 MOA (Minutes Of Angle). As you push your sights across the AP coordinate your trigger finger to break the shot just before your sights reach perfect alignment. This movement is very similar to the way a shotgun is fired. It takes practice to achieve high accuracy, but once you get the hang of it, you can take on difficult targets at high speed, with a great deal of success. The reason it works, has to do with how your muscles don't want to hold still as much as they want to move. You can apply a very smooth movement across the target, but you can't hold very still on target.

Standing Supported - In this position you will be erect behind shooting sticks, tripod, or rested against a support (tree, door frame etc.). Your rifle will be constrained at the point where the support occurs. If you choose to put the support near the balance point of the rifle, it will be easy for you to move up and down. If you put the support nearer the muzzle, you will have to make gross movements to change your point of aim, and those movements will by necessity be made by your entire body, or by repositioning the support. This position will feel very un-natural until you have practiced it a lot. It will also take quite a while for you to determine the correct length for adjustable legs, and position (fore and aft) on the rifle. One trick to really 'clean up' this position is to back into a tree or other stable support. You won't believe how much your upper body wants to move around until you constrain that movement. In standing supported you may find the sights are wandering all over the place just like standing unsupported, but if you watch closely, you'll see that they tend to oscillate in a typically circular pattern. By watching the pattern, you can predict when the sights will approach the AP. If you have excellent trigger control, you would take up 3/4 of the trigger weight as soon as your sights are close to the AP. Hold that. When your sights come around on their oscillation, take some of the remainder as the sights approach the AP, and hold as the sights depart. Continue this until you have what Col. Jeff Cooper called a 'surprise break'. This trigger technique is valid for all positions, at all times, but you will get the best training opportunity in Standing Supported.

A word about follow through; The ideal situation is for you to have zero reaction with the shot breaks. Be like a bag of sand, just absorb the recoil, hold the trigger, and DO NOT BLINK. That last one is perhaps the single hardest thing to do for most people. You will have to convince your subconscious first to delay the blink, then since 'nothing ever happens' to do away with the blink completely. Blinking is a reaction to an unexpected event typically recoil, or sound, or for scoped rifles, the loss of sight picture. Blinking will prevent you from seeing where your shot impacted, which will prevent you from making a correction if necessary. One technique I've used to overcome blinking is to become so engrossed in watching the scene unfold after a shot, pickup the trace, see the 'glint' from the bullet, watch for impact, etc. that I actually don't blink. It takes a while (unless you shoot tracers - that's a real shortcut!) until you can stall the blink response long enough to see anything of interest, then all of a sudden you will 'get over it' and be able to watch everything. Once you have that mastered, you can work on getting recoil to push your rifle straight back, and returning the rifle to 'battery' all during bullet flight time. If you want to work up in stages, I recommend you start by learning to hold your trigger all the way through the shot.

You will hear instructors mention 'The Fundamentals Of Marksmanship' very often. Mastery of the fundamentals is key to shooting accurately. So what are these fundamentals?

According to the US Army these are four fundamentals of Marksmanship:

Steady Position

Aiming

Breath Control

Trigger Squeeze

This is a link to the US Army Study Guide

The Washington State Criminal Justice Training Commission Patrol Rifle Course added the following:

Grip

Stance

Breathing

Sight Alignment

Sight Picture

Trigger Manipulation

Follow Through

This is a link to the document

Another US Army guide is much more simple:

Properly point the rifle at the target

Fire the rifle without moving it

This is a link to the web page, there are some very good graphics on this one.

Establish a solid shooting position.

Do not allow the barrel to come into contact with anything.

Front rest should be close to the front end of the stock, leaving sufficient room for recoil.

Rear rest should be close to the rear of the stock. Observe that the rear rest allows for 2-3 inches of rifle movement during recoil.

Position yourself behind the rifle so that your head on the stock is close to the same position as if you were standing. Often this can be accomplished by changing your seating height. One of the reasons I recommend a Drummer's Throne type of stool for bench shooting.

Position your right hand to lightly grasp the rifle and reach the trigger with the middle of the pad on the tip of your index finger.

Position your left hand to either operate the forward rest controls (elevation and windage), and/or squeeze and steer the rear bag. If your hand is near the rear bag when you shoot, make sure it is out of the area where the stock can hit it during recoil.

You should seat the rifle into your shoulder with no gap. If you leave a gap with a high recoiling rifle it will cause more discomfort. Do not pull the rifle hard into your shoulder, unless you can pull it the exact same way repeatedly. Try not to change the recoil dynamics.

Use tripod shooting sticks to support the front of your rifle for positions from prone to standing. There are short tripods for prone and taller much more adjustable tripods for everything else.

Use bipod shooting sticks when weight is an issue.

Use a stock mounted bipod when shooting from prone to sitting. Learn to pre-load the bipod so that the rifle will recoil naturally.

To pre-load a bipod; as the last step in building your natural point of aim shooting position, press your shoulder forward just enough to rock the bipod to it's forward limit of travel (which may be very small). Don't press hard enough to skid the feet. Ideally, at the moment of recoil, the bipod will rotate backward, and your shoulder will stop the recoil motion before the bipod feet skid in recoil. The idea is to enable the bipod to have the range of motion necessary to allow the rifle to recoil without the bipod feet moving.

Arrange so that the bipod legs can not move forward from the firing position

Press forward using only your shoulder on the butt of the stock until all slack is just removed from the bipod legs.

Under recoil the legs should allow the rifle to recoil in a straight line into your shoulder.

Use a backpack if nothing else is available.

Use a rear mounted monpod to support the rear of the rifle when possible.

This is the most stable position. For practical applications, this position is best used with a rest at both the forend and the toe of the stock. These rests may be tripod, bipod, or monopod devices, or bags designed for this purpose, or a field expedient rest composed of pack, jacket, rocks, logs, etc.

The forward rest should be located as far forward as is practical to reduce motion as much as possible.

The rear rest should be located under the toe (bottom) of the stock as far to the rear as is practical. The rear rest should be able to be adjusted by the shooters weak side hand to control elevation.

The rifle should be supported so that in recoil it moves directly to the rear.

The shooter should be positioned straight behind the rifle to absorb the recoil in a straight line. This promotes rapid return to the natural point of aim, which should also allow rapid re-engagement of the target.

For traditional match shooting where no rests are allowed, the shooter should use a sling (strap) to apply tension between the weak side upper arm and the sling swivel at the front of the stock. The sling shold wrap around the shooters arm, and have just the length to allow a tight position. In this position, the shooter should be aligned at an angle to the rifle so the weak side can support the rifle sling and create a triangular structure for support.

Learn to use a sling to steady the rifle. As mentioned above, a sling is not desirable for a fully supported prone position, however it does become useful for practical sitting, kneeling and squatting positions. Practical rile shooters should make a habit of constructing solid shooting positions with and without the use of a sling. For practical and hunting positions, creative use of the sling will add safety and support to the rifle system

Learn to avoid transmitting your brachial pulse to the sling.

In traditional match shooting shooters had to contend with their pulse being transmitted to the rifle system by way of the sling. The primary culprit is the brachial artery in the upper arm. The pulse effect can be mitigated by placing the sling above or below the center of the arm, and by padding at the source of motion.

Use a sling for stability.

Learn to shoot both cross legged and open legged.

Cross legged, place elbows over your knees, hook yourself into the position

Open legged place elbows into the 'pockets' of your knees and push out. For practical shooting, you can use a belt or rope to hold your knees together to significantly stabilize open legged sitting.

Use a sling for stability. Learn to place your weak side elbow over your week side knee.

A sling will only slightly improve stability in this position, and requires a significant time to adjust correctly. Learn to shoot 'free hand'. In standing there will be a lot of movement. Learn to control the oscillations so that your sights come onto the target predictably. Learn to squeeze as the sights approach alignment, then hold your squeeze until the sights begin to approach again. Successful shots from standing are often done quickly and dynamically (like shotgun shooting). Practice with low cost equipment and ammunition. Dry fire as much as you can.

Most of us are born with an innate desire to use one eye or the other to 'see' things. Assuming you start out as a youngster with equal eyes, you probably will develop a dominance in the eye on the same side as your 'handedness' eg; right handed and right eye dominant. If one eye is stronger it may become the dominant eye even though it is on the opposite side eg; right handed and left eye dominant. It is possible (and desirable) to at least be able to switch eyes with the hand that's doing the work. In the shooting world, this would manifest as being comfortable switching the eye you sight with when you switch the hand holding the firearm. Where rifles are concerned, it is extremely desirable to achieve the ability to be ambidextrous with both your hands and your eyes because of the way the rifle stock naturally places the sighting plane in line with the eye on the side where the rifle is being shouldered. There are any number of practical reasons to train yourself, and those you train, to be able to shoot proficiently from either shoulder. The same is true for handguns, however because there generally is no stock to shoulder fixed relationship it is possible to simply move the gun into line with the dominant eye.

There are several techniques that work. The following is one quick and simple way to show a shooter his or her dominant eye:

Place your hands together at full extension with your index

fingers and thumbs forming an opening.

Make the opening as small

as practical, say 2-3 times larger than the target, and use your

hands to block out as much of the rest as possible.

Look through

the opening at a distant (10 foot or so) target. It is important

that

the target be at least 10 feet to get this right.

While keeping

your concentration on the target, and your hands in the same

position, slowly bring the opening toward your face.

As the opening gets closer to your face it will tend to center up on the eye you are using. This indicates the dominant eye because no effort was made to choose an eye in the beginning.

Once you understand that the image you see is the composite of the images generated in both eyes (binocular vision), you will begin to understand how to mentally select the eye you desire to use.

Another drill that my father was taught in the Army in the 1920's uses just your index finger (either hand) held up like a front sight at arms length. Again the target must be at least 10 feet (or more) distant for this to work.

Look at the target. Focus on the target. Hold the tip of your finger just under the target (don't look at your finger, keep looking at the target). While you are looking at and focusing on the target, you should see two fingers, and both should be out of focus and appear semi-transparent. Each eye sees the finger from a different perspective, your brain puts the image of the target together in a single plane, and your finger(s) are in the foreground out of focus.

Here comes the fun part. While continuing to focus on the target pick one of the finger images and place it under the target. If you chose the left image, you are right eye dominant, if you chose the right image you are left eye dominant. Without changing anything else, close your right eye. Did the finger continue to be under the target? If it did, you are using your left eye, and the right image of your finger. If you open both eyes, then close the left eye you should see your finger jump out from under the target. If you happened to do it the opposite way, just reverse everything I just said.

The very useful part of the finger drill is that you can very quickly learn to move your 'chosen' eye from side to side, and you will learn what it feels like to choose an eye, and rapidly you will develop the ability to use either eye as your dominant eye.

If you are training someone in the finger technique, you use your (pick one) eye as their target, and run them through the close eye, switch eye, then to graduate with both eyes open consciously pick which eye to use. As the target, you will see the student's finger tip move back and forth between their eyes as they run the drill. If the student's finger gets stuck on their nose, try making the distance a little greater, or go back to explaining what a sight picture looks like.

If you have never tried an eye dominance drill like this one, I recommend you do so right this minute. Did you feel it 'pull' on your eye when you swapped dominance? That is like doing your first push up. Keep at it and you will be able to do it with ease.

When I get a few more minutes I'll try to sketch up this drill so you can see better what I am talking about, or just contact me if you have any questions.

As firearms technology progressed, it became apparent that a system was necessary to help the shooter point the gun at the target. Shotguns were found to work well with small bright beads, while rifles and pistols being that they fired single bullets, needed something more precise.

There are a number of variations on the front and rear sights that have been found useful over the years. Their purpose is always to align the barrel so that the bullet impacts where desired. Bullets do not travel in straight lines, and so sights for precise and long range work differ considerably from sights for short range fast work.

In this document, I am only going to cover rifles, and long range, so we will keep the discussion of sights confined to those useful for that purpose.

Open sights consist of a post or bead front sight, and a rear sight with some sort of notch to view the front sight through. The front sight must be centered side to side between the ears of the rear sight. A post front sight should be chosen to nearly fill the gap in the rear sight. The top of the front sight must be level with the ears of the rear sight. The sights should be zeroed so that the shot will hit just above the center of the front sight at your maximum point-blank-range.

The peep sight is designed to act as a very precise rear sight. In looking through the small hole in the center of the rear sight you will observe a vignette (shadow circle) with a clear center. The peep sight can increase depth of field much the same way that a camera aperture works. The center area is very small, thus ensuring a close alignment of the front and rear sight. The front sight may be any one of several designs; blade, post, circle, bead. Adjust the sights so that the shot hit the center of circles, or top middle of blades, posts, and beads.

Holographic sights project an aiming point so that it appears to be floating in the air before your eye. Because there is only one aiming point, and it follows the line of the barrel, it often appears to move more quickly than expected, and can wander all over the display area. Sights with a large display area make it easier to pickup the aiming point. A good way to develop speed with a holographic sight is to pretend the rifle is a shotgun and bring it to your shoulder while both watching the target, and paying attention to where the barrel points.

The ocular end of the scope is the end nearest to your eye, and the objective end is nearest to your target.

Ocular focus (focus the aiming point): The first step in adjusting a telescopic sight to your eyes is to adjust the ocular focus. Point the scope at a neutral (white) surface. Closer is better. You do not want to be able to look at the surface you point to, you only want to be able to see the reticle (aiming point). If the aiming point is out of focus, move the ocular focus to bring the aiming point into focus. Close your eyes for 10-20 seconds, then when you open them quickly determine if the aiming point is in focus. Make an adjustment to the focus. Repeat the quick recognition drill. Your eyes will bring the aiming point into focus if you continue looking too long. When you think you have the focus correct, wait a few minutes and do the quick recognition drill again. Continue adjusting focus until the aiming point is in sharp focus immediately, and stays that way.

Objective focus (remove parallax). Tactical and varmint telescopic sights have an objective focus. Typical hunting scopes have their parallax set to something like 100 or 200 yards and fixed there. The primary purpose of the objective focus is to remove parallax. You can determine if parallax is present by looking at a target through the scope while moving your head (and eye) slightly side to side, or up and down. If the aiming point appears to move on the target then you are observing parallax. If the aiming point remains stationary on the target then parallax has been removed (and the scope is focused at that distance). Tactical scope use a knob on the left side of the scope while varmint scopes allow you to screw the objective lens in and out to achieve focus. Both have a scale, usually in yards, to help preset focus. Typically even on high end tactical scopes the parallax adjustment numbers are incorrect. Always conduct a parallax check and adjustment before firing.

For quick action drills, and hunting or combat situations where time is of the essence, you can ignore parallax settings if you are confident your eye is in exact alignment with the centerline of the telescope. As you move your head in/out behind the scope, you will at some point begin to see a dark ring around the image. When the dark ring is the same size all around the image, your eye is centered, and although parallax is not removed, the cross hairs will be in the correct position relative to the target. This technique is most useful on fixed parallax hunting scopes.

Typical hunting scopes have ocular focus, elevation and windage adjustments. The elevation and windage typically are protected under a cap, and use a coin for turning leverage. US made hunting scopes typically have ¼ MOA adjustments, and may have a 'click' for each increment. Often the increments are quite different, and the adjustment rate is not very precise. Once adjusted to place a shot at the aiming point the scope is said to be zeroed. The distance at which this occurs is the scope zero range. Typical hunting scopes are zeroed at the beginning of the hunt, and shots taken at ranges beyond the point-blank-range, or to correct for wind are compensated by aiming away from the desired point of impact. In other words, the shooter may hold over the target so the bullet will impact the desired location. Hold over is very subjective and only allows for a little additional ethical range. You can use ballistics programs to suggest an optimal zeroing range for a given target size (ethical kill zone size). By adjusting the scope to place the bullet exactly in the center of the target at this range, you achieve the benefit of maximizing the allowable over and under impact so that you can aim directly at the desired point of impact for shots up to the maximum point blank range. Some shooters 'zero' their hunting scope to impact high at a closer range (typically 100 yards) by a certain amount (typically 1-1/2 inches). This technique has value, but is wildly inaccurate unless based on elevation obtained from ballistics programs which are given accurate information about all of the conditions involved.

Target scopes of a certain age were a tube with no elevation or windage controls built in, rather the scope mounts contained the machinery to point the scope, and adjust accurately in the desired range. In this setup, the scope often was allowed to slide front-to-back during recoil to protect the delicate silk thread, or natural spider webs that were used for cross hairs. Ocular and objective focus were the same as varmint scopes. Modern target scopes are often fixed power versions of tactical scopes. Tactical scopes have progressed to the point they are accurate enough for nearly all target work.

The modern tactical scope is able to resolve very small targets at very long ranges, has a wide zoom capability of 3, 4 or 5 times (ie 3-9 is 3 times, 3-12 is 4 times, 6-30 is 5 times), has very precise and repeatable adjustments that can be heard, felt and returned to the rifles zero point under adverse conditions. Nearly all tactical scopes have reticles that have an aiming point plus additional features to allow for accurate hold off and ranging. The modern tactical scope should feature reticle and knob calibration in the same angular measurement method, either MOA (Minutes of Angle), or MILS (Milliradians).

Mil-Dots: Mil stands for milli or 1/1000. In the case of scopes that's 1/1000 of a radian. A radian is an angular measurement system having π (Pi) radians per circle. There are 0.2908 MILS per MOA, or 1 MIL = 3.438 MOA. See MOA below

Mil-Dots come in several flavors, the US Marine Mil-Dot is a football shape, the US Army Mil-Dot is a circle. Mil-Dots are found almost exclusively in tactical scopes. Some tactical scopes use Mil-Dot reticles and MOA turrets, a situation that increases complexity for the shooter and spotter exponentially. Mil-Dot scopes with Mil turrets and FFP reticles are intuitive, but, for a shooter familiar with MOA, it takes time to become used to the larger MIL increments. The advantage is that turrets and reticles are provided in 1/10 Mil increments which while about 10% larger than ¼ MOA increments, and are easier to work with than fractions.

MOA stands for Minute Of Angle. In a circle of 360 degrees, each degree is composed of 60 minutes, each minute composed of 60 seconds. Most scopes sold in the US market have claimed MOA calibration, however many deliver IPHY (Inch Per Hundred Yard) divisions. 1 MOA = 1.0472" at 100 yards. 1 IPHY = 1.000" at 100 yards. Most US ballistic data is provided in MOA. The combination of MOA reticle and MOA turret in an FFP scope is very intuitive. Unfortunately MOA turrets and reticles are calibrated in fractions of an MOA, either ½ or ¼ MOA, increasing difficulty calculating adjustments. Some target scopes and peep sight have adjustments as small as 1/8 MOA.

FFP: A reticle placed in the first focal plane changes size proportional to the scope magnification so that any stadia on the reticle are useful at all power settings.

SFP: A reticle placed at the second focal plane remains constant size throughout the scopes magnification range. Any stadia (marks) on the reticle are accurate only at one power setting. The vast majority of hunting and inexpensive scopes in the US market are MOA and SFP type scopes.

Whether bench or position shooting, the expansion and contraction of your chest during breathing will move your point of aim significantly. The way to correct this is simply to stop breathing as soon as you acquire a sight picture, and complete the shot before you resume breathing. While it sounds easy, and it can become so second nature that you are not conscious of performing it, controlling your breathing does take some practice to perfect.

Generally accepted teaching is to inhale normally, exhale 1/3, and stop. Refine your sight picture, perform your trigger squeeze, and follow through. If you take too long, and that time is determined by how much oxygen your body is consuming at the moment, you will begin to become agitated and anxious, followed by tremors and loss of visual acuity. You can not make an accurate shot under those conditions, so before you start trembling you should hold your squeeze, maintain your sight picture, exhale, inhale, exhale, inhale and exhale 1/3, and pick up where you left off. You should not take particularly deep breaths, nor should you try to over oxygenate as this will cause you to be unstable for a period while you burn off the excess oxygen. With practice target acquisition, sight picture, breath control, and trigger control will become so deeply ingrained in your mind and body that you will be able to perform the entire sequence with no effort what so ever.

When shooting with a sling for support, particularly in prone, you may notice your front sight (or scope reticle) bouncing up and down in time to your pulse.

The brachial artery runs down the inside of your upper arm.

Your sling has come in contact with this artery, and your heartbeat is moving the rifle.

Placing a pad on the inside of your arm, or moving the sling up may eliminate the problem.

If you shoot enough, and you practice enough, you will discover that shooting accurately is more of a mental problem than it is a physical problem. About that time you may notice that you can control your heartbeat. It's a 'zen' sort of thing, and all I can tell you about how to do it, is to shoot about 1,000 rounds a week for several years while attempting to score X's on the old international smallbore target (the X is a speck in the center of a 0.22" circle fired at 50 feet), your shot must be within 0.11" of center to touch the X.

More realistically, a hunter may experience sever heartbeat interference due to exertion prior to the shot. A good way to mitigate the problem is to learn the 'free recoil' method of holding your rifle, wherein you have as little contact with the rifle as possible. It is always ethical to use any and all stability enhancing techniques as possible when hunting or in combat.

Triggers come in several types. The triggers that are most useful for accurate long range shooting are of a type that has little to no 'take up', that 'break' "like breaking glass", at pull weights around 3 pounds, and have very little over travel.

Target triggers that have these characteristics and break at ounces are only useful on the target range.

The advantage gained by the lighter weight trigger over the 3 pound trigger is minimal, and if you shoot much you will develop what I call an educated trigger finger.

The educated finger is confident in taking up the slack (2/3 of the trigger's pull weight) immediately. It is capable of holding any amount of tension on the trigger for several minutes (through many breathing cycles), and it is an expert at lying to you just enough that you don't quite know exactly when you have pulled enough to make the trigger go off.

The educated trigger finger takes its commands directly from the educated eye.

The brain only has executive control over the eye/finger team.

As the eye sees the sight picture approaching perfection, it tells the finger to increase tension.

The finger increases tension slowly until the eye tells the finger that the sight picture is deteriorating, at which point the finger holds what it's got, until the cycle repeats.

The brain can over-ride this coordinated effort to either abort the shot, or more likely it will anxiously interfere and make the finger mis-behave by jerking the trigger, which spoils the shot, which causes the brain great anguish.

When the brain does not interfere, the eye/finger team cause the gun to fire when the sights are correctly aligned, and an accurate shot results.

But because the brain wasn't really involved, there is no joy.

Paradoxically if joy and anguish get involved your shooting will suffer because your brain isn't very good at shooting. The more you get excited by a good shot, the less likely you are to be able to make a good shot.

The brain will play every trick in the book to get involved in the act of shooting.

One of the most difficult actions to perform is to ignore a shot, but that ultimately is what follow through is all about.

Another way to look at it, is that your brain really doesn't have a clue what time is, so it organizes things in a cause/effect sequence for you to experience. You brain lives in total darkness, it gets vision from sensors called eyes, tactile sensation from receptors all over your body (particularly sensitive places like your trigger finger), and sound from sensors called ears. While you are attempting to concentrate on breath control, sight picture, and trigger squeeze your brain is also worrying about things like "Is this shot going to hit the target?", "What is the recoil going to feel like?", "Am I going to get hurt by the recoil?", "Am I going to get hurt by the sound?" and about a million other things all at the same time.

The more you allow your brain to be involved in the act of shooting the more likely you are to make a bad shot.

One of the classic bad shot situations occurs when your brain makes your trigger finger jerk the trigger.

Another classic problem is when your brain tells your eyes to close to protect them from the 'Big Event' that's about to happen (gun goes off). You can't hit what you are aiming at with your eyes closed! So we need to keep the brain as far removed from the act of shooting as possible.

When I was learning to shoot, my coach told me that I could blink all I wanted AFTER the bullet hits the target. I spent several months telling my brain that it could blink AFTER the gun goes off, and now I just tell my brain that I don't need to blink AFTER the gun goes off, because NOTHING EVER HAPPENED that I needed to blink for.

Bottom line is that to shoot accurately and with precision the shooter must divorce his brain (emotions and self-preservation) from shooting. The eye/finger team must be trained and then allowed to function without interference, and the rest of the body is to act as a great large sand bag - no reaction - until well after the shooting stops.

Do not mess up the shot!

Don't jerk the trigger.

Apply smooth steady increasing pressure against the trigger.

Don't anticipate the shot.

It is natural to want to 'control the trigger', and make it go off when your eye says it should. This is the essence of 'eye-hand' coordination. It is also the source of one of the greatest violations of the fundamentals of shooting. It is inevitable; if you anticipate the shot, you will 'jerk' the trigger, disturb your aim, and miss the target.

To avoid anticipating the shot, squeeze the trigger with a slow steadily increasing pressure on the trigger. Force yourself to do this correctly by dry-firing (practice shooting without ammunition), until you think you have it. Then go to see how you are doing, practice with live ammo. The moment you detect trigger jerking, dry fire until you stop anticipating the trigger.

NOTE: One who has mastered the 'surprise break' described above may advance to the 'intentional break'. It is important the new shooter learns to hit so as to gain confidence, and experience. Once the shooter is ready to compete in timed events, or participate in coordinated fire it is time to learn how to stack or 'prep' your trigger and then 'command fire' the rifle. Attempting to do this before you have mastered the 'surprise break' will most likely result in trigger jerking of the worst kind.

Dry fire a lot. But, and this is huge. Dry fire perfectly.

Perfect practice creates the sequence that you will use when you do a task naturally without thinking out each step. To achieve perfection in position, sight alignment, and trigger control, practice dry firing so that each shot is done slowly and perfectly until you start to pick up speed. When you notice yourself messing up a shot, start over slowly and build back up to a natural rhythm.

Never practice bad habits. Correct them immediately so that your practice time is not wasted, and has the most benefit.

Don't muscle the gun.

To find your natural point of aim, (the position in whch your body naturally points the sights at the target).

Assume your shooting position with the rifle in firing position.

Close your eyes and settle into your cheek weld, grip, stance, etc.

Open your eyes and without moving the rifle, determine where you are pointing your sights. Correct your body position (stance) until you can repeat the sequence and the sights remain on target.

When done correctly, you should be able to maintain this position for hours at a time.

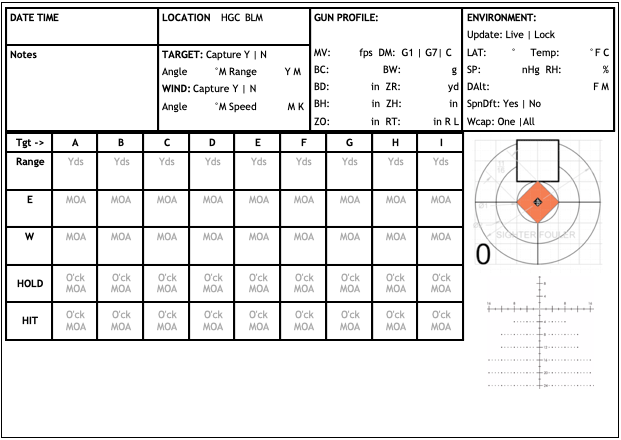

Call the shot.

Shooters use an O'Clock method to locate 'things' as a direction from a known reference point, and then either inches, MOA, or MILS to indicate the distance from the known reference point.

My wife has no end of problems with this, so I'm going to assume someone reading this is also having problems …

First – agree on the known reference point.

For 'formal' targets that's the Point Of Aim (POA), the center of the target, with 12 O'Clock straight up.

For conditions affecting the bullet or the shooter, the shooter is the center of the clock, with 12 O'Clock straight ahead.

For 'informal' targets, game and bad guys, the known reference point becomes some natural feature that is easily identified and communicated between shooters, and spotters. Again with 12 O'Clock straight up, or more likely straight ahead.

Context is key. There really are 3 clock faces. One for each plane of reference.

A horizontal direction from the shooter to the target is in the

horizontal plane with the clock laying on the ground centered on

the

shooter.

A radial direction on the target the clock is in the

vertical plane, center of the clock on the center of the target or

Point Of Aim (POA), with the clock facing toward the shooter.

A

vertical direction from the shooter to the target is in the

vertical

plane with the clock centered on the shooter and 9 O'Clock at the

horizon in front of the shooter and 12 O'Clock at straight up.

This

last one is so cumbersome the military dispensed with it decades

ago

and replaced it with “Position Angle” in increments of 10 degrees

Second – Superimpose a clock face on the known reference point, with 12 O'Clock straight up.

Third – Describe the direction to the thing of interest (bullet hole, new target, etc.) as the hour hand of the clock pointing toward the item of interest. Thus if something is above and to the left of the known reference point, it would be at 10:00 or 11:00 O'Clock. When you get more proficient it could be at 10:30.

Fourth – Describe the distance to the the thing of interest.

You can estimate distance at the target if you have a good feel for it. Could be in inches, feet, yards, meters, etc. Use the measurement unit that makes the most sense. This method is the least precise in most cases.

You can measure (or estimate) the distance as a function of the angle between the known reference point and the thing of interest. If your scope or binoculars have a grid for measuring angles, use that. The more you get used to using MOA or MILS to measure and correct your sights on a paper target, the better you will get at estimating distances in terms of degrees, or minutes / mils. The advantage here is that the shooter presumably has a reticle with the same measurement system, and can precisely locate the thing of interest.

One quick angular measurement is 'finger widths' – hold your hand at full extension and count the number of fingers between the point of reference and the object of interest – hold your hand so that the direction from the point of reference to the object of interest is at right angles to your fingers. After fingers run out, use the number of hand widths, etc.

Here is what FM 3-05.222 (Army Special Forces Sniper Training and Employment) says:

It is necessary that both the observer and the sniper know exactly what the other is doing and what he is saying when locating the target. Any method that is understandable to both and is fast to use is acceptable. They must use short and concise words to locate the target. Each must always be aware of what the other is doing so that the sniper does not shoot before the observer is ready. An example of this dialog would be:

Observer: “60 – HALF RIGHT, BARN, RIGHT 50 MILS, 2 O'CLOCK, LARGE ROCK, BOTTOM LEFT CORNER, TARGET.”

Sniper: “TARGET IDENTIFIED, READY” (or describe back to the observer the target).

Sniper: “TARGET IS 2 MILS TALL; 1 MIL WIDE.”

Observer: “SET ELEVATION AT 5+1, WINDAGE 0, PARALLAX 2D BALL.”

Sniper: “(repeats the direction upon setting the scope), READY.”

Observer: “HOLD OFF RIGHT” (wind correction). The sniper should have a round downrange within 1 to 2 seconds after the wind call.

It is extremely important that the sniper fires as soon as possible after the wind call to preclude any wind change that could affect the impact of his bullet. If the wind does change, then the observer stops the firing sequence and gives new wind readings to the sniper. The sniper and the observer must not be afraid to talk to each other, but they should keep everthing said as short and concise as possible.

The three methods of indicating targets are the direct method, the reference point method, and the clock-ray method. It is easier to recognize a target if the area of ground in which it is likely to appear is known. Such an area of ground is called an “arc of fire”. An arc of fire is indicated in the following sequence:

This axis (the middle of the arc).

The left and right limits of the arc.

Reference points (prominent objects). These should be as permanent as possible (woods, mounds), a reasonable distance apart, and easy to identify. A specific point of the object is nominated and given a name and range (mount-bottom left corner; to be know as mound-range 400) and recorded as such on the target card.

DIRECT METHOD

The sniper uses this method to indicate obvious targets. The range, where to look, and a description of the target are given. Terms used for where to look include the following:

Axis of arc – for targets on or very near the axis

Left or right – for targets 90 degrees from the axis.

Slightly, quarter, half, or three-quarters and left or right – for targets between the axis and the left or right limits.

REFERENCE-POINT METHOD

To indicate less obvious targets, the sniper may use a reference point together with the direct method, and perhaps the words above and below as well. For example:

300-mound (reference point – slightly right – small bush [target]).

200-mound (reference point – slightly right and below – gate [target]).

CLOCK-RAY METHOD

To indicate less-obvious targets, a reference-point target with a clock ray may be used. To use this method, it is imagined that there is a clock face standing up on the landscape with its center on the reference point. To indicate a target, the range the reference point and whether the target is to the left or to the right of it, and the approximate hour on the clock face are given. For example:

300-mound – right – 4 O'Clock – small bush [target].

When indicating targets, the following points must be considered:

Range. Its main purpose is to give an indication of how far to look but it should also be as accurate at possible, because this range may be used for aiming.

Detailed Indication. This value may require more detail than a normal indication; nevertheless, it should still be as brief and clear as possible.

The sniper can use mil (or MOA) measurements along with methods of indication to specify the distance between an object and the reference point used (for example, mound – reference point; go left 50 mils, lone tree, base of tree – target). Occasionally the use of hand angles will have to suffice. It is important that each sniper is conversant with the angles subtended by the various parts of his hand when the arm is outstretched.

If you want more information pickup reading at paragraph 4-170 on page 4-47 of FM 3-05.222

Assess the shot.

At the moment the shot goes off, you should be surprised and therefore you won't blink until well after the shot happens. Keep the image of the sight picture in mind at that instant. Where were your sights pointed?

Use the method described under 'calling the shot' to record where your sights were pointed, and where the shot hit. As your skill progresses, you will be more likely to accurately determine where your sights were pointed, and will find your shot impacting at or near that point.

If there was a problem with the shot, you jerked it, the wind changed, the target moved, etc. record that too.

Correct the sights or aiming point as necessary.

As you become proficient in calling your shot, and find your shots landing where you called them, you can use this information to make sight corrections more accurately than simply adjusting from the POA.

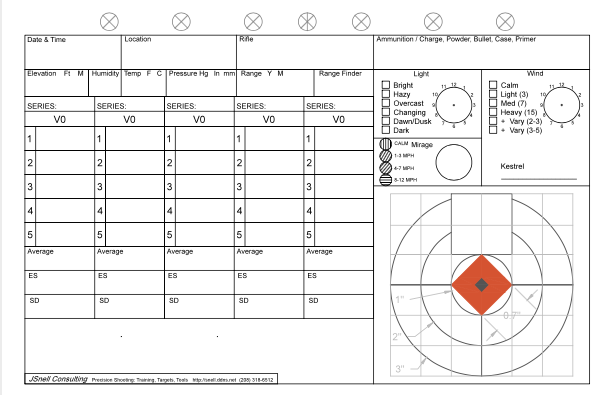

Log the shot.

Keep a record of every shot.

Refer to previous shots in similar conditions to establish a starting point for each new shot or group of shots. Your log book should contain the information listed under DOPE below.

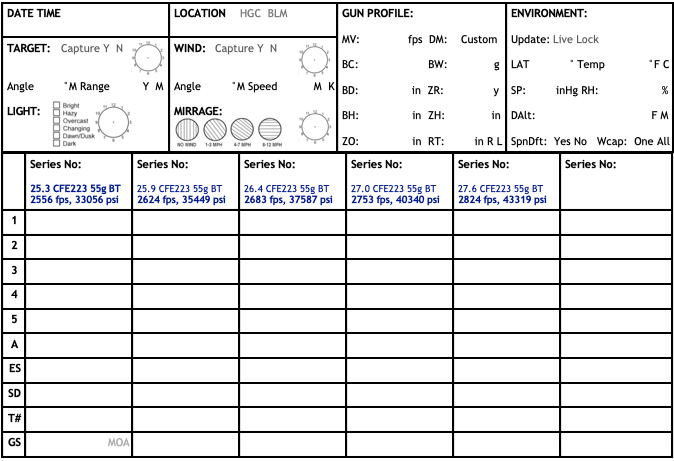

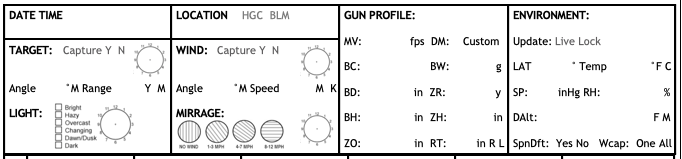

DOPE is what shooters have been calling their 'Data On Previous Engagements' since the early 1900's. It is a formalized method of recording critical information about each shot, with the goal of eventually providing sufficient information that the shooter can achieve first round hits on targets at extreme ranges under extreme conditions. Shooters keep a DOPE book for each rifle. Within the book there are sections for recording the data about the rifle, about the ammunition, about the target(s), and about each shot fired.

By categorizing, compartmentalizing, standardizing an recording information about each shot we take, we can build a reference work from with it is possible to gather, keep and use information we would otherwise loose. This information is valuable in allowing us to make corrections based on previous similar engagements and to allow us to modify our corrections based on changing conditions. We also gain a better memory of things like the number of shots fired through a barrel, and the effect various physical parameters have on our shooting. The DOPE book also contains charts and other reference material we may use to arrive at a firing solution.

NOTE: Even though there are many very good and accurate exterior ballistics programs available and even embedded into some of our environmental measuring equipment, keeping a DOPE book will have benefits as your memory of events, settings, conditions fades with time. The DOPE book is a journal designed to record both the technical data and the shooters observations.

The most useful location data includes Latitude and Longitude because as you learn to shoot longer distances the direction of fire over the earth, as well as the location on the earth become important to the calculation of the firing solution.

At the very least use a location you can find and refer back to with LAT/LON when you get to that point.

Time of year indicates a general set of parameters in case you don't have the ability to measure them directly.

Establishes chronological order.

Above or below Sea Level in feet or meters.

Elevation abbreviations:

ASL (Above Sea Level).

AGL (Above Ground Level), 'Angels'.

Station pressure (the absolute pressure where you are) is the number you need. You can get this number from the sea level pressure and your altitude and temperature, or simply get this number from a local barometer (Kestrel, iPhone app, etc.)

Generally in the US this value is in inches of mercury (in/hg).

The dry bulb (shade) temperature at your location. In the US in degrees Farenheit. (ºF)

The percentage of water in the air. (%RH)

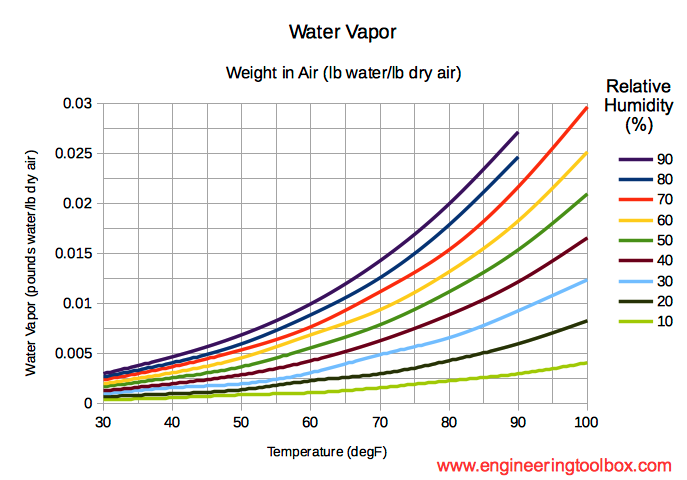

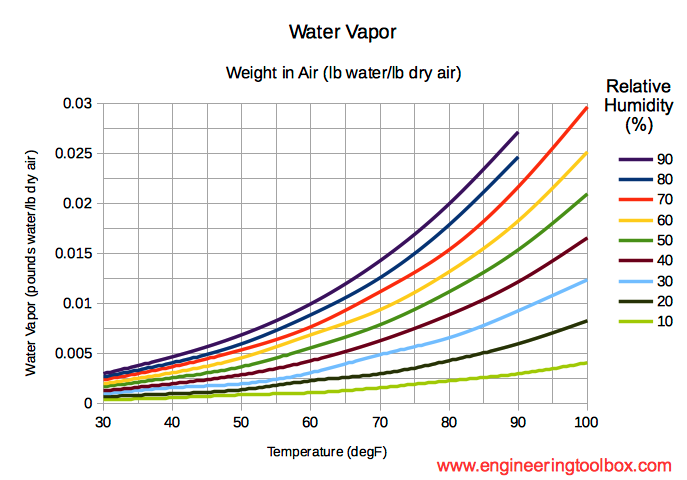

As the temperature

goes up, the air becomes thinner (density goes down).

As the temperature goes up, the amount of water in the air for a given humidity level goes up.

Air density is the 'thing' that causes drag, which is the 'thing' that causes us to have to adjust our sights for varying distances

Air density plays a major role in trajectory (change in bullet velocity over distance).

Thinner air has less resistance to bullet travel eg. drag (increased altitude or lower pressure).

Higher Relative Humidity generally indicates lower air density, and lower drag.

Air density plays a minor role in wind drift and is generally discounted for drift calculations.

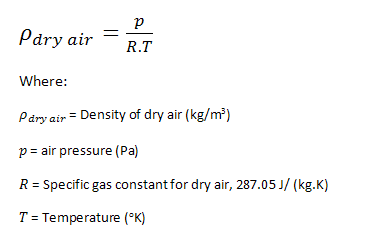

Air Density can be computed from the values recorded for Pressure (station), Temperature and Humidity by the formula:

To

use the formula above, you need to convert your temperature from

Fahrenheit to Kelvin

The formula to make this conversion is:

K = (y °F + 459.67) x 5/9

To convert 75 F to Kelvin this

would look like:

K = (75 °F + 459.67) x 5/9

K = 534.67 x

0.555

K = 297.038

For your DOPE it is sufficient to record pressure, temperature

and

humidity.

Including altitude will permit referencing the results

to standard atmosphere at sea level should you ever desire to do

so

at a later date using the formulas above.

Various kinds of overcast can affect how you see your sights. This is more prominent with iron sights, but still is valuable with all types of sights.

Each of these conditions affects how you see objects and perceive dimensions, distances, size, shape and movement.

Bright – No clouds at all.

Hazy – Haze or smoke (stuff between you and your

target)

Overcast – Some clouds. Estimated % cloud

cover.

Changing – Clouds periodically blocking sun, casting

racing shadows.

Dawn or Dusk – Sun near horizon, very low angle

light, often light hitting bottom of clouds, very long shadows.

Dark

– Sun is totally obscured by heavy clouds, or has gone below

horizon.

Light, particularly coming from low angles, or from directly overhead, distorts shadows that your brain has been trained to use in recognizing the scene your eyes are viewing.

Light coming directly toward you can blind you to what lies in the smallest of shadows.

Particularly with iron sights, but still applicable to telescopic sights the view of your aiming point varies under extreme lighting conditions, and point of impact may change in a predictable way as the result. Logging the direction of illumination will help you re-create a scene for training, and will help you avoid previous errors.

The ability to 'read' the wind, and to 'estimate the wind' are vital to successful long range shooting because for a typical long range cartridge, after the bullet has traveled about 500 yards, the displacement of the bullet by the wind is far greater than the combined error of the shooter and the ammunition. A successful long range shooter must be able to integrate the wind over the course all the way to the target and provide a 'wind call' consisting of the wind speed and direction (always reported as the direction from which the wind blows) to an accuracy of about one mile per hour.

Anemometers are tools that are calibrated to display the speed of the wind, and optionally act as a weather vane to indicate the direction of the wind.

To achieve accurate readings, the typical shooters anemometer must be aligned so that the full force of the wind acts upon the detector. Aligning the detector so that it is parallel to the path of the bullet will not produce the correct wind speed because the detector (usually a propeller) does not react proportionally to the prevailing wind, but rather tends to record the maximum wind from a wide angle of presentation.

The anemometer only informs of the local wind. Observation of the wind downrange will determine if this reading can be used reliably, and will provide indications of variations in wind patterns the bullet will encounter on the way to the target.

First, it is important to know that the wind that affects the bullet initially (wind at the firing point) is often going to have the largest impact on the location of the bullet downrange. This is because once the bullet has been deflected, there is no force, except another wind, that can move the bullet back toward it's unaltered course.

Second, it is important to note that winds downrange can and will affect the path of the bullet, sometimes adding to the deflection, other times subtracting from the deflection the bullet experiences at the firing point. These wind effects can be added together as a 'vector summation' to arrive at a total deflection. When doing so, however it is necessary to include the increased time the bullet spends in each say 100 yards of range, due to velocity reduction induced by drag. More time in a given wind will result in larger deflection.

In locations with totally open flat surface between shooter and target the wind is likely to be fairly similar across the entire distance. If grass is long enough to react to the wind, you may see 'bands' of wind 'rippling' across the grass. This effect is due to the way the wind is blowing in rolling circular bands and can help you figure out the percentage of the effect across the course.

Learn to 'read the wind' by observing wind in everyday activities. If you have the opportunity to spend time in rugged terrain you will notice that wind often follows the slop. In the morning, in still air, you will be able to see that the sun heats the air toward the top before it heats the air at the bottom. Hot air rises, pulling the cooler air up the hill. In the afternoon, the shadows in the deep valleys cool sooner than the air at the top reversing the flow. This continues regardless of the weather, but local wind is often much stronger than convection flow. When wind encounters an upslope it compresses (and heats up) toward the bottom, then flows up the slope. When it encounters a ridge, or a ridge top, convection occurs which causes a swirling rolling wind. This effect occurs even for surface changes as subtle as dry grass versus irrigated crops.

This French word comes from the Latin mirare or 'to look at.' In

a

shooting context it has come to mean an optical illusion caused by

atmospheric conditions.

Mirage begins when air moves (due to

wind) or when the ground surface heats from solar radiation and

warms

the air that is in close proximity to the surface. Warm air rises

because it is less dense than colder air. Air temperature effects

how

light is bent passing through the region. As the air heats and

rises

it creates a shimmering wavy appearance by deflecting the light

that

passes through the region.

Initially this effect moves straight up in calm air and appears as vertical wavy lines, quite pronounced when viewed through magnification. As the effect continues, and the day progresses, wind will occur as cooler, denser upper air is drawn to replace the lighter warmer air near the surface. This wind will cause the vertical wavy lines to tilt.

The bottom of the wavy line will stay put where the heat caused the air to expand, and the top of the wavy line will move in the direction of the wind. When viewed through magnification (spotting scope or telescopic sights) the direction is nearly impossible to determine because of the two dimensional nature of the image.

The strength of the wind can be measured quite accurately for low speed wind, by the angle of the mirage.

15° tilt is caused by 1-3 mph wind

30º tilt is caused by 4-7

mph wind

90º tilt is caused by 8-10 mph wind

But keep in mind that what you observe may not be a wind at 90º to your line of sight. The 15° tilt you see, may be a 30º tilt viewed from 45º. Observing the motion of wind downrange for several minutes and across the width your 'front' will provide you with clues as to the direction of the wind.